BLOG

Elegoo Saturn 3 Ultra 12K Troubleshooting and Maintenance: Essential Tips for Optimal Performance

Elegoo Saturn 3 Ultra 12K is your go-to 3D printer! Discover essential troubleshooting and maintenance tips to enhance performance and print quality. Our guide covers everything from cleaning to optimizing settings, ensuring you get the most out of your printer. With our practical advice, you’ll keep your Elegoo Saturn 3 Ultra 12K running smoothly and efficiently, making your 3D printing experience even more enjoyable!

Understanding the Elegoo Saturn 3 Ultra 12K

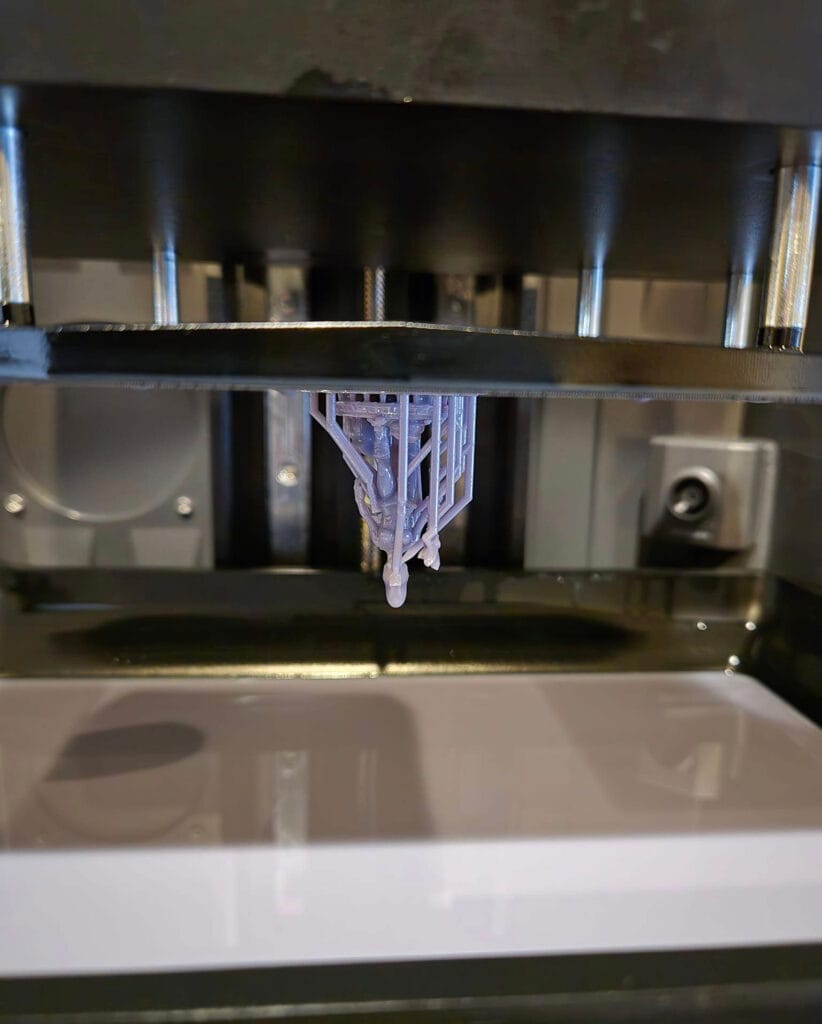

Before diving into troubleshooting and maintenance, let’s take a moment to appreciate what makes the Elegoo Saturn 3 Ultra 12K a standout choice among resin printers. This model boasts a resolution of 12K, which translates to incredibly fine detail in prints, setting a new standard for quality in the 3D printing world. The printer also features a large build volume, making it capable of producing sizable models or multiple smaller items simultaneously, thereby enhancing productivity.

Key Features and Advantages

- 12K Resolution: With a staggering pixel density, the Saturn 3 Ultra 12K allows users to achieve unprecedented levels of detail. This is particularly beneficial for applications such as miniatures, jewelry, and intricate designs, where precision is paramount.

- Generous Build Volume: Measuring 218 x 123 x 250 mm, the printer accommodates larger projects without compromising on detail, making it a versatile option for both hobbyists and professionals.

- Fast Print Speeds: Time efficiency is a critical factor in 3D printing. The Saturn 3 Ultra 12K offers reduced print times without sacrificing quality, enabling users to complete projects more quickly.

- Compatibility with Various Slicing Software: The printer’s flexibility extends to software compatibility, allowing users to choose their preferred slicing programs for optimal workflow.

The Importance of Regular Maintenance

Regular maintenance is vital for sustaining the performance and longevity of your Elegoo Saturn 3 Ultra 12K. Neglecting maintenance can lead to issues such as failed prints, mechanical malfunctions, and reduced print quality, ultimately hindering your creative projects. By committing to a regular maintenance routine, you can enjoy smoother printing experiences and maintain high-quality results.

Essential Routine Maintenance Practices

1. Cleaning the Printer Regularly

External Cleaning

Start your maintenance routine by focusing on the external surfaces of the printer. Dust and resin residue can accumulate over time, affecting both appearance and performance. Use a lint-free cloth slightly dampened with isopropyl alcohol to gently wipe down the body of the printer, the control panel, and any acrylic components. Regular external cleaning helps keep your printer looking new and prevents dust from interfering with the electronics.

Internal Cleaning

For internal cleaning, the resin vat and LCD screen require particular attention. Carefully remove the resin vat from the printer. Use a spatula to scrape off any resin residues from the FEP film without damaging it. Clean the vat with isopropyl alcohol to ensure it’s free of contaminants before reusing.

When cleaning the LCD screen, use a soft, dry microfiber cloth. Avoid using any liquids directly on the screen, as this could cause damage. Instead, if necessary, lightly mist the cloth with isopropyl alcohol before wiping the screen gently. Keeping the screen clean is essential for preventing print failures and maintaining quality.

2. Updating Firmware

Checking for Updates

Just like your computer or smartphone, your 3D printer benefits from regular firmware updates. New updates can improve printer performance, add new features, and fix existing bugs. To check for updates, visit the Elegoo website or consult the user manual for the latest firmware version available for your model.

Performing Firmware Updates

Updating the firmware is a straightforward process. First, download the latest firmware version from the Elegoo website onto a USB drive. Next, insert the USB drive into your printer. Power on the printer and follow the on-screen instructions to initiate the update. Make sure your printer is connected to a stable power source during the update to avoid any interruptions that could render the printer inoperable.

Troubleshooting Common Issues

As a user of the Elegoo Saturn 3 Ultra 12K, you may encounter various issues during operation. Understanding how to troubleshoot these problems can help you get back to printing swiftly and effectively.

1. Print Quality Problems

Layer Adhesion Issues

One of the most common problems is poor layer adhesion, which can result in prints that are weak or incomplete. To address this issue, begin by checking the leveling of your build plate. A properly leveled build plate is critical for ensuring that the first layer adheres well. Use a piece of leveling paper or a feeler gauge to ensure the distance between the build plate and the LCD screen is consistent across all corners.

Adjusting your slicing settings can also help. Increasing the exposure time for the initial layers can improve adhesion significantly. Start with a longer exposure time for the first few layers and gradually decrease it for subsequent layers to optimize print quality.

Surface Finish Problems

A rough or uneven surface finish can detract from the overall appearance of your prints. This issue may stem from various factors, including print speed and settings. Adjust your lift speed and retract speeds in your slicing software. A slower lift speed can help reduce the chances of surface imperfections. Additionally, using higher-quality resin designed for fine details can significantly enhance the finish of your prints.

2. Mechanical Issues

Misalignment and Leveling

If you notice issues with misalignment, regularly check the alignment of your build plate. Use a leveling tool to ensure the plate is level and that there’s no wobble. If necessary, loosen the screws that hold the build plate in place, level it again, and retighten the screws. Proper alignment is crucial in mitigating misalignment problems that can lead to failed prints.

Resin Leakage

Another concern is resin leakage, which can occur when the FEP film is damaged or improperly installed. Signs of leakage typically appear as resin puddles beneath the printer. If you detect leaks, inspect the resin vat and the FEP film for any visible damage or tears. If the FEP film is scratched or compromised, it will need to be replaced. Follow the manufacturer’s instructions for replacing the FEP film, ensuring a secure and proper fit to prevent future leaks.

3. Software and Connectivity Issues

Connection Problems

Connection issues between your printer and computer can be frustrating. If your printer is not recognized by your device, start by checking all USB connections. Ensure that the USB cable is firmly connected to both the printer and the computer. Restarting both the printer and your computer can often resolve many connectivity problems.

Software Compatibility

Ensuring that your slicing software is compatible with the Elegoo Saturn 3 Ultra 12K is also essential for optimal printing performance. Make sure you are using the latest version of the slicing software that supports your printer. Utilizing software specifically optimized for resin printers can significantly impact print quality and success rates, so invest time in finding the best one for your workflow.

Advanced Troubleshooting Techniques

As you become more experienced with your Elegoo Saturn 3 Ultra 12K, you may encounter more complex issues. Here are some advanced troubleshooting techniques to keep in your toolkit.

1. Diagnosing Hardware Issues

Identifying Faulty Components

If you suspect hardware issues, it’s crucial to systematically check each component of your printer. Use a multimeter to test electrical components, looking for any signs of malfunction. Listen for unusual sounds during operation—grinding, clicking, or excessive noise can indicate a problem with the stepper motors or other mechanical parts.

Replacement Procedures

When it comes to replacing parts such as the LCD or FEP film, follow the manufacturer’s instructions carefully. Always opt for genuine replacement parts from Elegoo to maintain the performance and reliability of your printer. Additionally, document any repairs or replacements for your records, helping you keep track of the printer’s maintenance history.

2. Optimizing Print Settings

Recommended Settings for Different Resins

Every type of resin comes with its own optimal print settings. Familiarize yourself with the recommendations provided by resin manufacturers, which typically include ideal exposure times, lift speeds, and other specific parameters. This knowledge will allow you to tailor your settings for each print job, ensuring the best results possible.

Troubleshooting Print Failures

In the unfortunate event of a failed print, analyze the problem thoroughly. Look for signs of underexposure, overexposure, or misalignment. Keeping a log of your print adjustments can help you identify patterns in successful and failed prints, allowing you to refine your processes over time.

Encouragement and Community Support

Engaging with the User Community

Joining online forums or social media groups dedicated to the Elegoo Saturn 3 Ultra 12K can provide valuable insights. Users often share their experiences, troubleshooting tips, and solutions to common issues. Engaging with fellow enthusiasts can enhance your understanding and offer new perspectives on 3D printing.

Manufacturer Support

If you encounter persistent issues that you can’t resolve, do not hesitate to contact Elegoo’s customer support. They are equipped to assist with warranty claims and provide guidance on resolving specific problems. Additionally, familiarize yourself with the various resources available on Elegoo’s website, including user manuals and troubleshooting guides, as these can be invaluable tools in your 3D printing journey.

Conclusion

Proper maintenance and timely troubleshooting are crucial for ensuring your Elegoo Saturn 3 Ultra 12K operates at its best. Regular cleaning, firmware updates, and adherence to manufacturer guidelines are essential for maintaining print quality and prolonging the printer’s lifespan. By understanding common issues and how to address them, you can minimize frustrations and maximize the potential of your resin printer.

With dedication and a willingness to learn, you can harness the full capabilities of your Elegoo Saturn 3 Ultra 12K, creating stunning prints that showcase your creativity and skills. Happy printing!

FAQs

- How often should I clean the resin vat? Clean the resin vat after every print to prevent buildup and contamination. Use isopropyl alcohol and ensure it is dry before the next use.

- What should I do if the print is not adhering to the build plate? Ensure the build plate is level, clean, and possibly sanded lightly for improved adhesion. Adjust initial layer exposure time and ensure the resin is well-mixed.

- How can I prevent layer separation or delamination in my prints? Maintain proper exposure settings, a clean environment, and high-quality resin. Ensure the printer is level and the build plate is securely fastened.

- What should I do if the LCD screen is not displaying correctly? Check for resin spills or dust on the screen and clean it. Restart the printer and check connections. If the issue persists, contact customer support.

- How can I fix print artifacts or distortions in my models? Adjust print settings, ensuring resin is well-mixed and the printer is on a stable surface. Update firmware and use optimized slicing software settings.

- What steps should I take if the Elegoo Saturn 3 Ultra 12K is making unusual noises? Check for loose or worn-out components, tighten screws, lubricate moving parts, and inspect the Z-axis for smooth movement.

- What are some common print quality issues and their solutions? Common issues include layer lines, warping, and incomplete prints. Solutions involve adjusting exposure settings, maintaining cleanliness, and inspecting/replacing the FEP film.