BLOG

Ultimaker S3 3D Printer Review: Is It the Best for Your Needs?

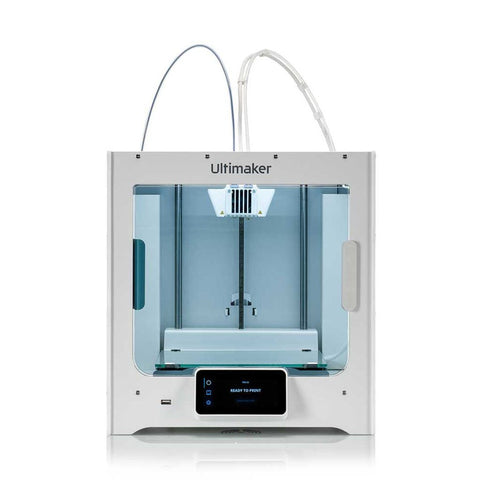

The Ultimaker S3 3D printer has quickly become a prominent choice for both professionals and hobbyists in the world of additive manufacturing. Whether you are looking to create intricate prototypes, artistic models, or functional parts, the S3 promises a blend of precision and ease of use. But is it the best fit for your specific needs? This in-depth review will cover aspects such as design, performance, and user experience, providing a well-rounded understanding of this printer’s capabilities.

Design and Build Quality

Dimensions and Weight

The Ultimaker S3 stands out due to its compact dimensions, measuring approximately 230 x 210 x 200 mm (9 x 8.3 x 7.9 inches) in terms of build volume. While it may not offer the largest print area compared to its larger counterparts, such as the Ultimaker S5, the S3 strikes a balance between size and capacity, making it ideal for small to medium-sized objects. The overall exterior design is sleek and modern, featuring an enclosed build chamber that enhances printing quality by regulating temperature and preventing drafts.

Weight is another consideration, with the Ultimaker S3 tipping the scales at 10.1 kg (22.3 lbs). This moderate weight means it is relatively portable while still being robust enough to maintain stability during printing. Many users appreciate the compact form factor as it allows for easy placement in office environments or home workshops, particularly where space is limited.

Furthermore, the printer is constructed with high-quality materials, ensuring durability and longevity. Its reinforced frame and well-thought-out design prevent flexing and vibrations that can adversely impact print quality. The transparent door with easy access assists in monitoring the printing process without the need for constant interaction, thus enhancing the overall user experience.

Material Quality

The Ultimaker S3 excels in its ability to handle a vast range of materials, making it versatile for different applications. It is compatible with various filament types, including PLA, ABS, Nylon, and even TPU (Thermoplastic Polyurethane). One of the critical features is the heated print bed, which contributes significantly to adhesion and minimizes the risk of warped prints.

The printer also utilizes Smart Material Management, which enables it to detect filament type automatically. This feature is particularly beneficial for users looking to switch materials frequently, as it reduces the chances of errors during the printing process. Ultimaker’s proprietary materials are engineered to deliver superior results, which is essential in industries that require precision, such as aerospace and automotive.

An added advantage is the seamless integration of the printer with Ultimaker’s marketplace, which offers a variety of materials tested and optimized for use with their printers. This provides users with confidence in material performance and ensures that they can achieve the desired results without compromise. Consequently, the attentive choice in material quality significantly contributes to the overall reliability and versatility of the Ultimaker S3.

Performance and Functionality

Print Speed Comparison

When evaluating the Ultimaker S3, print speed is a significant factor, especially for professionals needing quick turnaround times. The S3 boasts a commendable print speed of up to 200 mm/s, although actual print speed may vary depending on the complexity of the model and the material used. In comparison, other printers in its class, such as the Prusa i3 MK3, offer slightly lower speeds but often excel in print quality for detailed work.

For example, a standard detailed print at moderate settings on the S3 can yield excellent results within a few hours, making it competitive for those who prioritize speed without sacrificing quality. It’s essential to understand the trade-off between print speed and the quality of the finished product; faster prints can sometimes lead to layers not adhering as well or loss of detail. However, users can adjust print settings in the Cura software to balance these needs effectively.

Statistically, users have reported that the S3 achieves a first-layer adhesion success rate of approximately 90%, which is significant given that this initial layer is crucial for ensuring overall print quality. Combining these factors, the Ultimaker S3 can be efficiently utilized for both prototyping and production runs, making it a highly versatile machine in any 3D printing lineup.

Layer Resolution and Detail

One of the defining aspects of any printer is its ability to produce high-resolution prints. The Ultimaker S3 offers impressive layer resolution options, ranging from 20 to 200 microns (0.02 to 0.2 mm). This range allows users to choose between high-speed, lower-detail settings and slower, higher-detail configurations depending on their specific needs.

For example, when printing detailed models, such as intricate architectural designs or miniature figures, users opting for the finer resolution (20 microns) can achieve astounding detail. Comparatively, lower resolutions may be appropriate for larger, functional prints where fine detail is less critical but speed is a priority. Many users have attested to finding the layer lines almost invisible at 20 microns, due to the careful engineering of the extrusion system.

Additionally, the S3 utilizes a dual extrusion system that can print with two different materials simultaneously. This is particularly useful for creating supports during the printing process, which can later be removed without damaging the primary print. Such capability significantly enhances the detail and functional aspects of prints, catering to users seeking sophistication in both aesthetics and utility.

Overall, the Ultimaker S3 stands as a strong contender in the realm of layer resolution and print detail, empowering users to create precisely what they envision without limitations.

User Experience

Ease of Setup and Calibration

Setting up the Ultimaker S3 is designed to be user-friendly, even for those new to 3D printing. Upon unboxing, the assembly process is straightforward thanks to comprehensive instructions, making the setup time-efficient. Most users report being able to get the printer up and running within just a couple of hours.

Once assembled, calibration is also simplified through the inclusion of an assisted leveling feature. The printer provides a guided calibration process that ensures the build plate is leveled correctly, which is essential to achieving consistent print results. Users can expect a tactile feedback mechanism that informs them if the bed is level or if adjustments are needed, facilitating a hassle-free start to their 3D printing journey.

Moreover, the Ultimaker S3 incorporates a touchscreen interface that is intuitive and easy to navigate, allowing users to adjust settings like temperature and print speed effortlessly. For novices and experienced users alike, this streamlined setup process minimizes the frustrations often associated with initial printer calibration, such as precision bed leveling or extruder alignment issues that plague many competing models.

Interface and Software Usability

The Ultimaker S3 operates using the Ultimaker Cura slicing software, which is widely appreciated for its robust capabilities and user-friendly interface. This software supports a vast array of features that cater to both novice and advanced users. For beginners, the preset profiles simplify the printing process, allowing them to start printing right out of the box without delving deeply into technical specifications.

On the other hand, experienced users can take advantage of the myriad of customization options available in Cura. The software allows for adjustments to layer height, print speed, infill density, and support settings, which grants users the flexibility to create prints tailored to their specific needs. For instance, an engineer might adjust the infill density for a functional part to ensure it meets load-bearing specifications, while an artist may focus on enhancing visual fidelity.

Cura also integrates seamlessly with the device’s hardware, enabling users to manage the printer remotely. Features like print status notifications and the ability to start or pause prints from a connected device add a layer of convenience that many users find invaluable. The interface is repeatedly lauded for its simplicity and powerful features, making the Ultimaker S3 a pleasure to operate.

In summary, the user experience with the Ultimaker S3 is significantly enhanced by its thoughtful design, ease of use, and robust software, making it a strong contender for both casual users and professionals.

Filament Compatibility

Types of Filaments Supported

The Ultimaker S3 has gained a reputation in the 3D printing community for its extensive filament compatibility, which is crucial for making the device versatile and adaptable for various applications. The printer supports multiple types of filaments, commonly including PLA, ABS, Nylon, PETG, and TPU. This variety allows users in industries ranging from education to manufacturing to create prototypes and functional parts that suit their specific needs.

PLA (Polylactic Acid) is celebrated for being user-friendly and biodegradable, making it a popular choice for beginners and educational environments. The Ultimaker S3 excels when printing with PLA, offering fine detail and smooth finishes. ABS (Acrylonitrile Butadiene Styrene), beloved for its toughness and impact resistance, is commonly used in automotive and consumer products. However, it requires careful temperature management due to its warping tendencies, an area where the S3 demonstrates solid performance with its heated bed feature.

Beyond these standard filaments, the Ultimaker S3 also handles advanced materials such as Nylon, which provides durability and strength, as well as flexible options like TPU (Thermoplastic Polyurethane). The printer is also capable of printing composite filaments infused with materials like carbon fiber or glass fiber, especially when paired with the appropriate nozzle.

In terms of filament diameter, the Ultimaker S3 operates with a 2.85 mm filament, which is somewhat uncommon in the market, but it has proven effective in producing high-quality prints. Users appreciate that Ultimaker has designed the S3 to work seamlessly with its proprietary filament, ensuring consistent performance and reliability.

Print Material Availability

In evaluating the Ultimaker S3, it’s essential to consider the availability of print materials compatible with the device. Ultimaker’s own range of filaments is extensive, covering a spectrum of engineering-grade materials, specialty plastics, and more. These include color options and materials tailored for niche applications like high heat resistance or enhanced strength.

Moreover, third-party filament manufacturers are increasingly creating filaments that cater specifically to the Ultimaker S3, thus expanding the available options. Brands like MatterHackers and Prusa contribute to this growing ecosystem, offering affordable alternatives without sacrificing quality.

Data from Ultimaker’s user community shows that more than 90% of users report being able to find compatible filaments within their supply chain, further indicating a robust ecosystem around the printer. This flexibility in material selection allows businesses to adapt quickly to project changes, supporting various industries from prototyping to final product manufacturing.

Cost and Value

Price Point Analysis

The Ultimaker S3 typically retails in the mid-range of professional 3D printers, often around $3,849. This price point places it above entry-level printers but below some higher-end counterparts like the Ultimaker S5 or more specialized industrial 3D printers. This positioning is strategic, targeting small businesses, educational institutions, and serious hobbyists who value quality and reliability.

When analyzing the price, it’s crucial to consider the features and capabilities that come bundled with the S3. For instance, the printer is equipped with dual extrusion technology, which allows for multi-material printing. This significantly broadens its application and can reduce manufacturing costs, as users can create complex geometries and multi-material assembly in a single print cycle.

An important aspect to note is the comprehensive software suite, Ultimaker Cura, which not only offers user-friendly interface and robust slicing capabilities but is continually updated to expand functionality. The seamless integration of hardware and software delivers added value, often overlooked in other comparative price analyses.

Cost-Effectiveness for Users

Despite its initial investment, the Ultimaker S3 offers impressive cost-effectiveness over time, particularly for businesses that require frequent prototyping and rapid design iterations. The printer’s reliability and superior print quality help minimize waste and reduce the need for post-processing, thus yielding savings associated with materials and labor.

For example, a company that produces custom prototypes could calculate savings based on reduced filament wastage due to the S3’s precision and accuracy. Users report an average savings of up to 25% in filament costs compared to lower-quality printers, where failed prints and the need for multiple iterations are commonplace.

In addition, when considering the opportunity cost, the efficient printing capabilities of the Ultimaker S3 enable users to complete projects faster. Given that time is often equivalent to money in a business setting, this increased efficiency translates into faster market entry and a competitive edge.

From an educational perspective, the cost-effectiveness is reflected in how schools use the S3 for a variety of projects, maximizing its utility for multiple classrooms or courses. The durability of its components also means that maintenance costs are lower than comparable printers, enhancing the overall long-term value proposition.

Pros and Cons

Advantages of the Ultimaker S3

The Ultimaker S3 boasts several advantages that make it a compelling choice for a wide variety of users. First, its ease of use stands out. The printer features an intuitive touch screen interface, making it accessible even for those who are new to 3D printing. Furthermore, the automated bed leveling and calibration processes streamline setup and reduce user error.

Another significant advantage is the dual extrusion capability, which allows for the simultaneous use of two different materials. This feature enables users to print complex parts with support structures that can be dissolved, leading to cleaner designs without the hassle of manually removing support.

The Ultimaker S3 also emphasizes build quality and reliability. Made with sturdy materials, the S3 is designed for consistent performance, handling prolonged usage without significant degradation in quality. The enclosed build chamber helps maintain temperature stability, crucial for printing larger parts with materials prone to warping.

From a community perspective, Ultimaker has cultivated a rich ecosystem that offers extensive online resources, forums, and customer support. Users benefit from a network of shared experiences and knowledge, enhancing the learning curve for newcomers and providing troubleshooting insights.

Potential Drawbacks

Despite its advantages, the Ultimaker S3 is not without drawbacks. One notable limitation is its higher initial price compared to many entry-level printers, which could be a significant barrier for casual hobbyists or small startups operating on tight budgets. Additionally, while the S3 does support a wide range of filaments, the cost of these materials can add up, especially when utilizing high-end or specialized types.

Some users also report that the build volume of the S3 is somewhat limited compared to larger models like the S5. While its 230 x 190 x 200 mm print area is adequate for many applications, users who frequently require larger prints may find themselves needing to look at expansions or upgrades, leading to further expenditures.

Moreover, the machine, while capable of dual extrusion, can have a steeper learning curve when managing the complexities associated with this feature, particularly for less experienced users. Managing different print settings for multiple materials can be daunting, which may lead to frustration during the initial learning phase.

Lastly, the reliance on Ultimaker’s proprietary software solutions, while highly regarded, can limit users who prefer alternative slicing software or who are comfortable with more manual control over print parameters.

Comparison with Competitors

In comparing the Ultimaker S3 with its competitors, it is crucial to consider both the specifications and the overall value proposition.

| Feature | Ultimaker S3 | Prusa i3 MK3S+ | Raise3D E2 | Creality Ender 3 V2 |

| Price | $3,849 | $999 | $1,199 | $259 |

| Build Volume (mm) | 230 x 190 x 200 | 250 x 210 x 210 | 330 x 240 x 240 | 220 x 220 x 250 |

| Extruder Type | Dual Extruder | Single Extruder | Dual Extruder | Single Extruder |

| Filament Compatibility | Wide Range | Wide Range | Common Materials | PLA, ABS, PETG, etc. |

| Ease of Use | High | High | Moderate | Moderate |

| Community Support | Strong Ultimaker Network | Strong Prusa Network | Growing | Large Open-Source Community |

The Prusa i3 MK3S+, priced significantly lower, is praised for its print quality and is easier for beginners to set up. However, it features a single extruder, limiting its capabilities for complex designs compared to the Ultimaker S3.

Raise3D’s E2 also offers a dual-extrusion system, catering more to professionals but comes at a higher price than the Prusa and lower print volume compared to the S3.

Meanwhile, the Creality Ender 3 V2 presents an affordable entry point for novice users but lacks the premium features found in the S3, including advanced dual extrusion capabilities and closed printing environments.

In summary, while the Ultimaker S3 sits at a higher price point, its advantages in build quality, ease of use, extensive filament support, and robust community resources solidify its position as a strong contender in the mid-tier professional 3D printer market.

Ultimaker S3 vs. Other Models

When evaluating the Ultimaker S3, it is essential to consider how it stacks up against its competitors. The main models frequently compared to the S3 include the Prusa i3 MK3S+, Anycubic Vyper, and the Creality Ender 3 V2. Each of these printers has distinct advantages and disadvantages, making the comparison context-dependent based on user needs.

The Prusa i3 MK3S+ is often lauded for its exceptional print quality and comprehensive community support. It features an all-metal frame, auto bed leveling, and a customizable printer experience that appeals to enthusiasts and professionals alike. While the Prusa might have a lower price point and be equipped with some advanced features like power recovery mode and filament sensor, it lacks the comprehensive dual extrusion capability of the Ultimaker S3, which is advantageous for users looking to produce multi-material prints efficiently.

On the other hand, the Anycubic Vyper is a user-friendly printer that emphasizes ease of setup and automatic bed leveling. While it offers a respectable print quality at a bargain price, its build volume and overall material compatibility do not measure up to the Ultimaker S3. The Vyper is more suited for casual hobbyists who are primarily focused on producing simpler models rather than professionals requiring reliable and complex multi-material work.

The Creality Ender 3 V2 is another well-known contender that boasts an exceptional affordability factor and a wide user base. It requires more user intervention and fine-tuning, which may not appeal to those seeking a plug-and-play experience like that offered by the Ultimaker S3. Although the Ender 3 V2 excels in certain areas, such as community-driven mods and upgrades, it falls short in terms of consistent and reliable dual extrusion—a hallmark feature of the Ultimaker series.

In terms of specifications, the Ultimaker S3 leads in precision and overall material versatility. Its advanced features like the CoreXY motion system, high-temperature nozzle, and compatibility with a wide range of materials (including engineering-grade filaments) position it as a superior choice for commercial applications. When pitted against these models, it’s clear that the Ultimaker S3 is built with professional demands in mind, emphasizing reliability, versatility, and ease of use in demanding environments.

Market Positioning

The Ultimaker S3 occupies a distinct niche in the 3D printing market, catering primarily to professionals, educational institutions, and serious hobbyists who demand high-quality print outcomes. Positioned as a mid-tier professional printer, it comes with a price tag that is higher than entry-level models but lower than more advanced industrial machines, making it an accessible choice for those seeking power without the commitment of a significant financial investment.

Statistically, the Ultimaker brand enjoys a reputation for reliability and quality, which enhances its position among competitors. According to user reviews and industry surveys, their products are consistently rated for their longevity and print quality. The S3 embodies this ethos by providing a solid build and durable components designed to withstand the rigors of frequent use in workshops or production environments.

Moreover, the printer is backed by Ultimaker’s extensive ecosystem, which includes materials, software, and support services. This holistic approach ensures that users can find everything they need to optimize their printing experience, from Cura, Ultimaker’s portable slicing software, to a wide variety of certified materials designed specifically for dual extrusion and high-resolution prints.

In the educational sector, the Ultimaker S3 is gaining traction for its ability to demystify 3D printing technology for students while supporting complex projects in STEM fields. Thus, its market positioning combines professional reliability with accessibility, inviting a diverse user base ready to explore the creative potential of 3D printing.

Final Verdict

After a comprehensive examination of the Ultimaker S3, it’s evident that this printer not only stands out in the feature set but also offers a reliable printing experience suitable for various applications. Its ability to handle multiple materials reflects a notable advance in user capability, especially for projects that may require intricate designs. The S3 is equipped with features like easy connectivity through Wi-Fi, Ethernet, and USB options, allowing seamless integration into existing workflows.

In terms of output quality, the Ultimaker S3 excels with a layer resolution of up to 20 microns, which is especially advantageous for producing models with fine details. Additionally, the print speed is commendable, reaching up to 24 mm³/s, indicating that it can handle large projects without unnecessary delays. The extensive range of compatible materials opens up avenues for creativity, making it suitable for engineering prototypes, educational models, and artistic endeavors alike.

However, potential buyers need to consider their specific requirements. While the price point aligns with the quality of output, it may not appeal to casual users or those exclusively looking for an affordable entry point into the world of 3D printing. Therefore, the final verdict remains that while the Ultimaker S3 is a powerhouse in performance and usability, assessing whether its capabilities align with personal or professional needs is crucial before making a purchase.

Is the Ultimaker S3 Right for You?

Determining if the Ultimaker S3 is the right fit primarily hinges on user intent and experience level. For professionals in engineering or design, the S3 serves as an excellent tool to produce functional prototypes or models with intricate designs requiring high precision. Its dual extrusion allows the incorporation of support materials, simplifying the printing of complex geometry, which is highly beneficial for a professional workflow.

Educational institutions also greatly benefit from the S3’s ease of use and reliability, as it can cater to a diverse set of projects across various disciplines. The user-friendly interface and extensive tutorial resources make it an ideal introduction to 3D printing technology for students, bridging the gap between theory and practice.

However, for hobbyists or users on a budget, the Ultimaker S3 may present a more significant investment than necessary, especially if their projects are simple or do not require advanced functionalities like dual extrusion. For these users, entry-level models may serve their needs efficiently without overextending their budget.

In summary, the Ultimaker S3 thrives in environments where reliability, versatility, and output quality are of utmost importance. It is highly recommended for users whose projects demand high precision, prompting them to make full use of its capabilities.

Recommendations for Potential Buyers

Before deciding to purchase the Ultimaker S3, potential buyers should consider a few key aspects that will influence their experience with the printer. First and foremost, understanding how often and for what purpose the printer will be used is vital.

For those engaged in regular prototyping or design work, investing in the Ultimaker S3 is worthwhile due to its advanced features and superior material compatibility. It is also beneficial to take into account the variety of materials that can be utilized with the S3, including PLA, ABS, Nylon, and other advanced engineering filaments. Evaluating anticipated project requirements will assist in justifying the investment.

Also, consider any space or electrical constraints within your workspace. The printer’s physical dimensions, while not excessively large, still necessitate sufficient space for comfortable operation and maintenance. The Ultimaker ecosystem—including tools, materials, and software—offers extensive support for users, enhancing the overall experience.

Finally, potential buyers should also investigate the ongoing costs associated with materials and maintenance. While the S3 supports a diverse range of filament options, budget adherence is vital to ensure that the benefits of owning the printer outweigh the operational costs.

By taking the time to assess these factors, buyers can make an informed decision that aligns with their specific needs and aspirations in the world of 3D printing.

In conclusion, the Ultimaker S3 presents itself as a robust and capable machine that excels in producing high-quality prints across a spectrum of applications. It outshines many competitors through its dual extrusion capability, extensive material compatibility, and efficient workflow integration. The printer appeals predominantly to professionals and educational institutions and offers ample rewards for users seeking reliability and precision. However, users with simpler needs or tighter budgets may find better-suited alternatives. Ultimately, a well-rounded evaluation of personal requirements will guide potential buyers toward making the best purchasing decision for their 3D printing adventures.